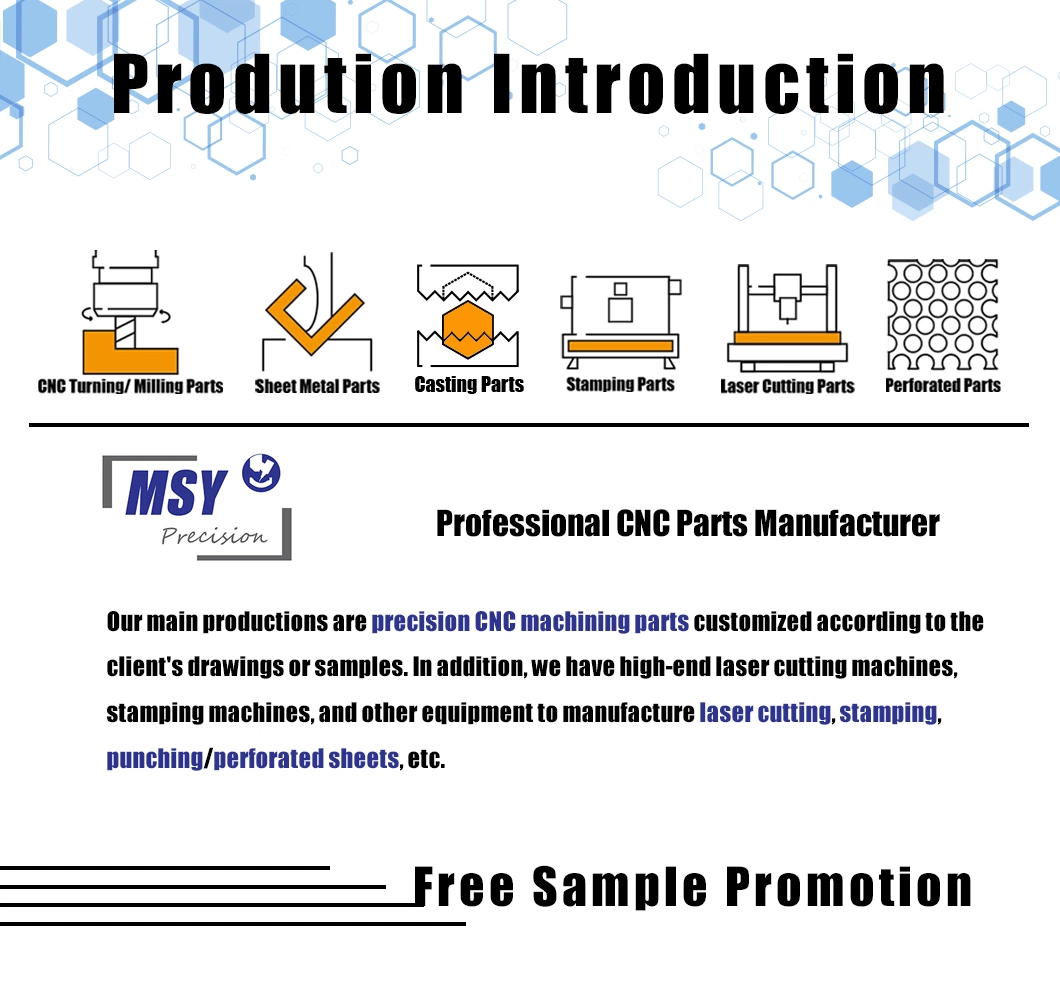

CNC Machining Precision Parts Vacuum Quenching Turned/Milled Mechanical Parts

Technical Support Our engineers are skilled in Auto CAD, Pro Engineer, Solid Works, and other 2D & 3D software. We are a

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | PP0223 |

| Material | Stainless Steel |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery, Car Parts, Precision Equitment Parts |

| Service | One Stop Service, Machining-Assembly |

| Machine Type | Turn, Mill, Drill, Weld, CNC Lathe, CNC Center |

| OEM/ODM | Yes |

| Micro Machining or Not | Micro Machining |

| CNC Machining or Not | Machining Services |

| Fabrication | Customized as Drawing/Sample |

| Roughness | Ra 0.2-3.2 |

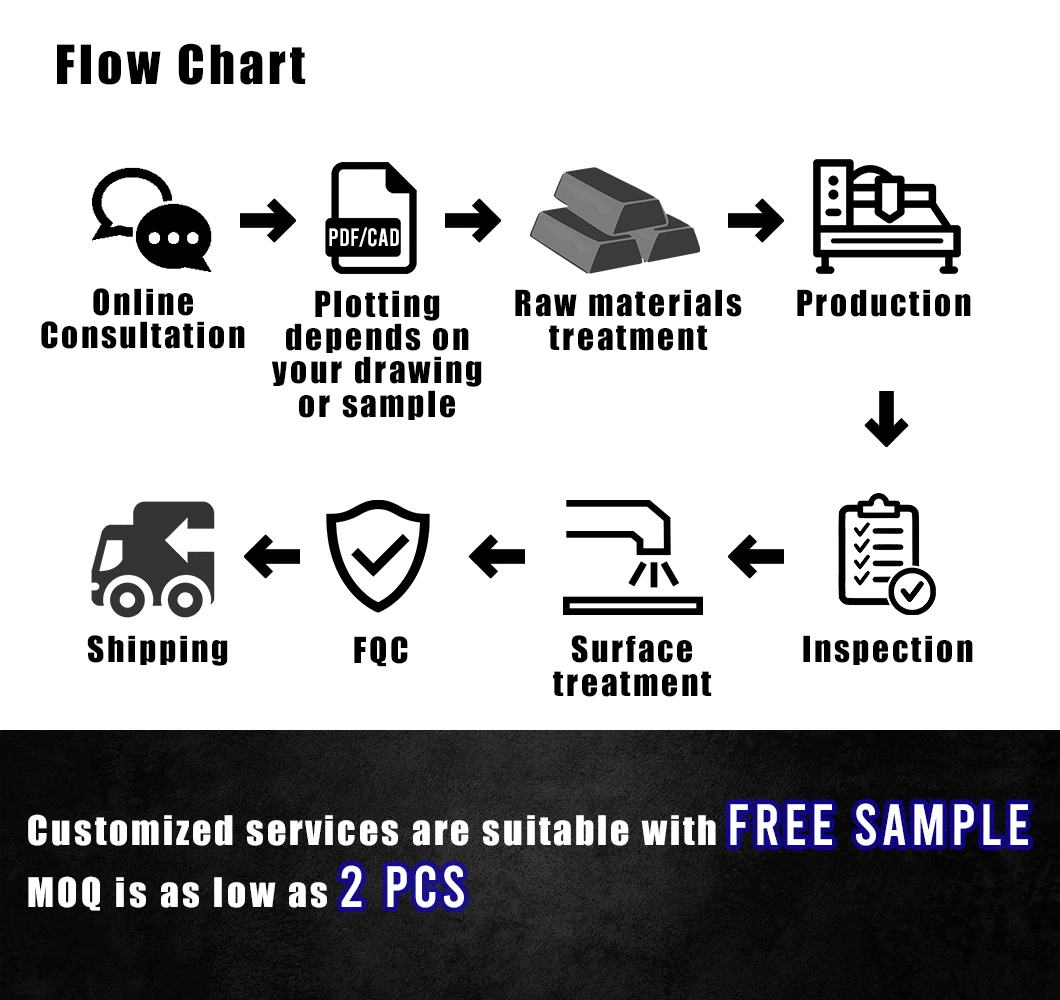

| Delivery Time | 15 Workdays or as Quantity |

| Sample Lead Time | 7 Days |

| Tolerance | ±0.002 - 0.1mm |

| Surface Finish | Anodizing, Polishing, Plating, Heat Treatment, etc |

| Transport Package | Foam & Carton Box |

| Specification | OEM & ODM As Drawing |

| Trademark | OEM/ODM |

| Origin | Dongguan, China |

| HS Code | 8479909090 |

| Production Capacity | 1000000 |

Product Description

Technical Support

Our engineers are skilled in Auto CAD, Pro Engineer, Solid Works, and other 2D & 3D software. We are able to design, develop, produce and deliver your products according to your drawings.

We can supply products with the following test reports:

1. Chemical composition report2. Tensile strength report3. Brinell hardness report, Rockwell hardness4. Key dimensions checking record report5. Third-party test report

Quality Control

1. Checking the raw material after they reach our factory2. Checking the details before the production line operated3. Have a full inspection and routing inspection during mass production4. Checking the goods after they are finished5. Checking the goods before they are packing

Why us

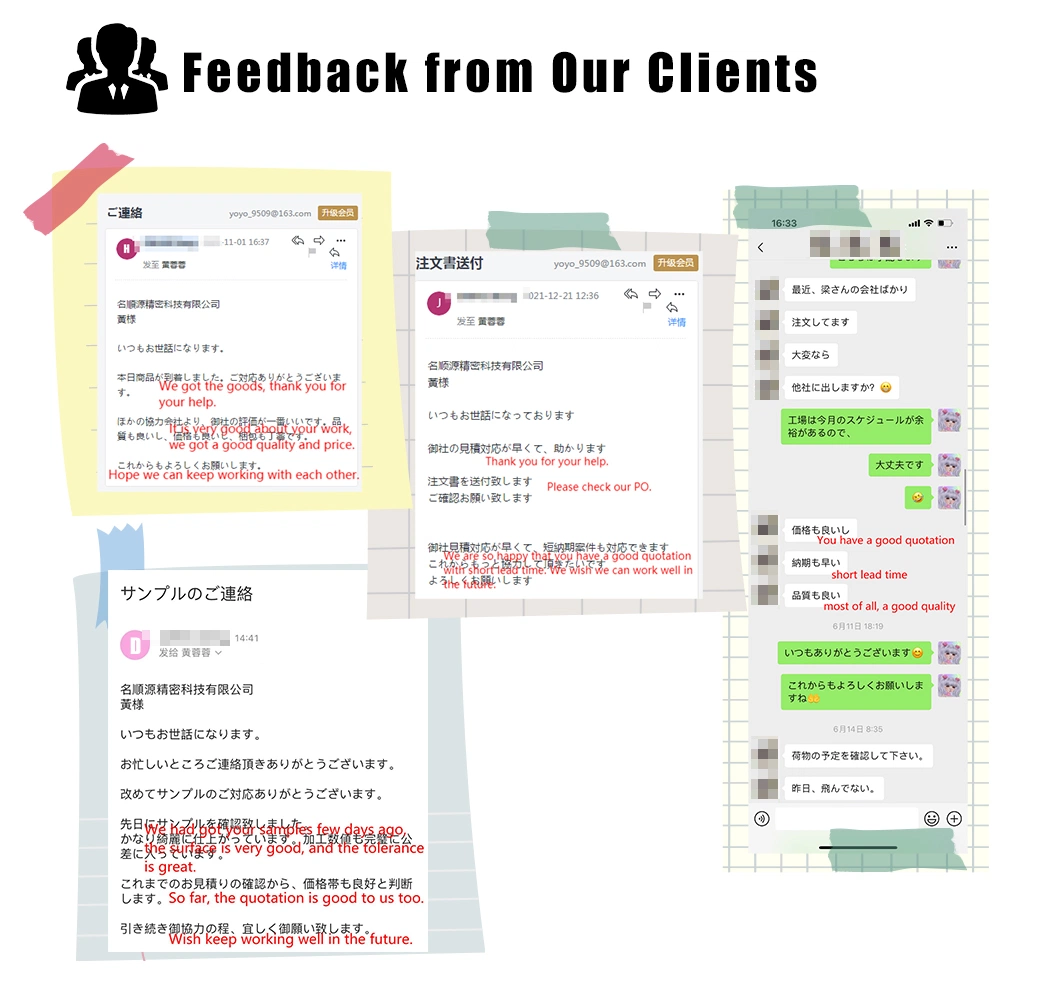

1. Design assistance and full engineering support.2. Professional at OEM/ODM CNC parts.3. Complete production lines for custom turning, milling, CNC machining sheet metal fabrication, stamping, bending, welding, and surface treatment.4. Advanced machine tools, CAD/CAM programming software.5. Prototype machining capabilities.6. Strict quality control standards with a highly qualified inspection department.7. Low-cost solutions for sampling.8. MOQ is as low as 10 pcs.

Q&A

| Q: What do I need to offer a quote? A: Please offer us 2D or 3D drawing (with material, dimension, tolerance, surface treatment, and other technical requirement etc.), quantity, application, or samples. |

| Q: What's your MOQ? A: Our MOQ is 10 pcs, trial orders are welcome. |

| Q: What's the production cycle? A: It varies greatly depending on product dimension, technical requirements, and quantity. Usually, it's around 10- 30 days. |

| Q: What kind of payment terms do you accept? A: T/T. |

| Q: Is it possible to know how is my product going on without visiting your company? A: We offer a production schedule and send weekly reports with pictures or videos to show the machining progress. |

Related Products