OEM Custom Aluminum Precision Metal CNC Machining/Machined/Machine/Machinery Spare Parts CNC Milling/ Lathe/Turning /Die Casting /Welding Part Service for Auto

Overview We are committed to providing advanced CNC machining service to clients with stable quality, fast delivery and

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | QJ-027 |

| Inner Diameter | 20-22.5mm |

| Width | 701-800mm |

| Drawing Format | Powermill CAD Mastercam Creo Hypermill |

| Logo Service | Support |

| Tolerance | 1100X650X550mm |

| Surface Finish | Sandblasted/Anodized/Plated/Customized |

| Leadtime | Within 15 Days |

| MOQ | Prototype Is Acceptable |

| Inspection | Fqc, IQC, Pqc, Oqc |

| Machine Type | 5/4/3 Axis |

| Trade Terms | Fob/CIF /EXW |

| Shipment | as Your Request |

| Shipping Port | Shenzhen Port |

| Unique | China Gold Supplier |

| Supply | Drawing Design |

| Technics | Precision Machining |

| Item | Machining Part, Turning Part, Milling Part, etc |

| Transport Package | Carton Boxes with Wooden Pallets |

| Specification | aluminum |

| Trademark | QJ |

| Origin | Dongguan |

| Production Capacity | 50000 Pieces/Year |

Product Description

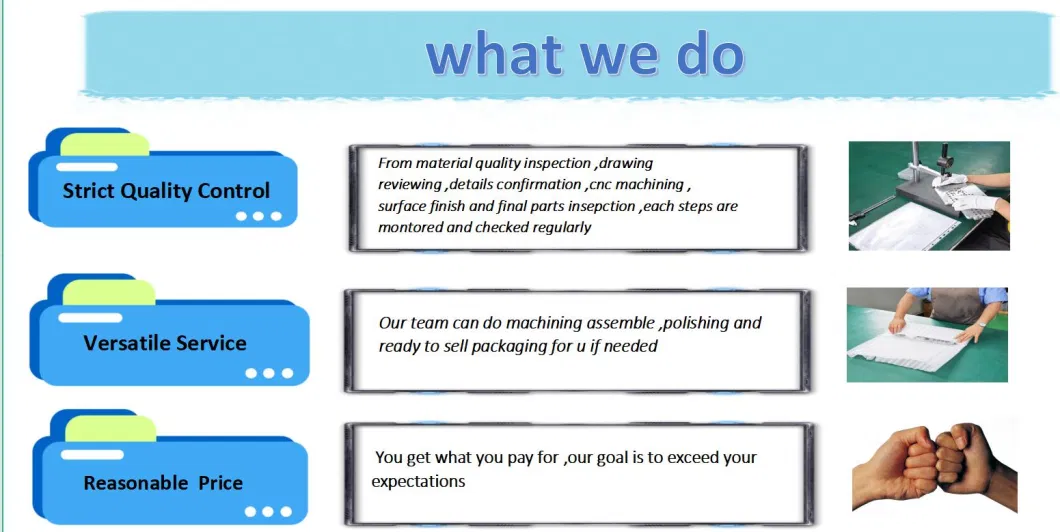

We are committed to providing advanced CNC machining service to clients with stable quality, fast delivery and low cost. Contact us today to request a free quote.

Product DescriptionCAD Model DesignThe CNC machining process begins with the creation of a 2D vector or 3D solid part CAD design. The CAD software allows designer to produce a model or rendering of their parts along with the necessary technical specifications, such as dimensions and geometries.Once the CAD design is completed, the designer exports it to a CNC-compatible file format, such as STEP or DXF.

CAD File ConversionThe formatted CAD design file runs through CAM software to extract the geometry of the custom-designed part and generates G-code which will control the CNC machine and manipulate the tooling to produce the custom-designed part.The operator need to loads the CNC program to the machine once it is generated.

Our Ability

We have a large number of machines to meet Turning/Milling/Drilling/Stamping etc. different processing, such as CNC machining center 3-Axis, 4-Axis and 5-Axis, CNC lathe machine, CNC automatic lathe machine, Punching machine, grinder, precision internal/external grinding, wire cutting, spark machine, etc. The detection equipment: projector, altimeter, digital micrometer, digital caliper, quick gauge, plug gauge, internal/displacement gauge and other high-precision testing instruments, the detection accuracy up to 0.001mm. Surface TreatmentWe can provide Polishing, Surface Chamfering, Hardening and Tempering, Nickel plating, Chrome plating, zinc plating, Laser engraving, Sandblasting, Passivating, Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, etc. Mail Product

Our Advantages

. Complicated shapes can be machined in a single setup to improve productivity and accuracy

. Ability to use shorter cutting tools to increase cutting speed and reduce tool vibration

. Save money and shorten delivery time with less fixture preparation

. Achieve superior surface finish and overall better part quality

CNC machining is essential in many industries such as aerospace, automotive, energy, industrial machinery and medical, etc.These machines are also critical to other manufacturing processes. For example, the mold required for injection molding is CNC machined to ensure the accuracy of the mold and the plastic parts it makes.

1

Q: Are you trading company or manufacturer ?

A: We are direct factory with experienced engineers and employees as well as well-organized workshop.

2

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

3

Q: Do you provide samples ? is it free or extra ?

A: Yes, the sample fee depends on the product geometry, and the fee will be returned to your bulk order.

4

Q: How long can I get the sample?

A: Depends on your part geometry, normally within 3-7 days.

5

Q: How long is your delivery time?

A: Sample 3-7days; Mass production order 7-45 days depends on quantity and part complexity.

6

Q: What is your terms of payment ?

A: Payment<=1000usd, 100="">=1000USD, 30% T/T in advance ,balance before shippment.

7

Q: What's kinds of information you need for a quote?

A: Kindly please provide the product 2D drawing with PDF or DWG format and 3D drawings with STEP or IGS or X_T format, and other requirements like: surface treatment, quantity...etc.