Metal Parts Rapid Prototyping by CNC Processing and Manufacturing

Metal Parts Rapid prototyping by CNC Processing and Manufacturing [Factory Show] [About Us] So far,we are the one of the

Send your inquiryDESCRIPTION

Basic Info.

| Finished | Hard Anodized |

| Company Location | Zhongshan |

| Quality Control | 100% Inspect Before Shipment |

| Trade Methods | EXW, Fob, CIF, CFR, DDP, DDU |

| Size | Customized |

| Lead Time | Short |

| Price | Low |

| Drawing File | Igs, STP, Pdf |

| Name. | CNC Machining |

| Transport Package | Standard Exported Packaging |

| Specification | ISO9001, SGS |

| Trademark | HL |

| Origin | Guangdong |

| HS Code | 8108909000 |

| Production Capacity | 100000PC/Month |

Product Description

Metal Parts Rapid prototyping by CNC Processing and Manufacturing

[Factory Show]

[About Us]

So far,we are the one of the top manufacturer exported parts to foreign countries through alibaba and made in china website frequently,our clients are in the high standard quality field.

We look forward to your kind cooperation!!!

Quality is our cultures! (we will provide High-end produced with good quality, excellent in workmanship, best service)

1. Small details make big difference. We promise: All the parts from our company have no sharp edge. Holes and screw holes are chamfered for convenient assembly (Under no indication). Every product will be carefully packed to prevent the bump and rust in transit .

2. The craftsmanship of all parts we machined is controlled rigorously. Every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors.

4. Each size of product must be tested one to one after completing production and provide quality report.

5. We not only have the world of high-end DMG five-axis linkage machining center, the five-axis linkage turning compound double spindle machining center, compound turning machine, but also have more than 30 sets of processing machines from Japanese and Taiwanese brands. Our testing equipment are imported from Japanese brand, such as high-end automatic three coordinate measuring machine, the two coordinate measuring machine, high-quality height gauge and roughness measurement etc.

6. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is lower, at least reducing the trade company's service fee.

7. We are a combination of production and trade, industry and trade integration business. So far there are 15 traders for US and European market

8. Because we are more close to our factory, we can understand the actual situation of our factory, we are more professional ,more reasonable and more accurate than trade company. And our language ability is also diversified. We can communication Spanish, English and Russian.

9. We have a good enterprise culture with various professional training programs, early meeting every day to share our work experiences to grown up together happily. We have a great ability to development in the company.

10. There are around 80 staff in our team, everyone has their dream in our company. All of us hold birthday celebration, celebrating Mother's and Father's Day , traveling together. The company respects every employee, when Woman's Day coming, we got the beautiful flowers and wishes from brothers. Happiness and care surrounding us since we live here, feeling extremely happy !

we love our company as much as own family, also love dear customers.

[Product Description]

| Material: | Aluminum (6061-T6, 6063, 7075-T6,5052) etc... Brass/Copper/Bronze etc... Stainless Steel (302, 303, 304, 316, 420) etc... Steel (mild steel, Q235, 20#, 45#) etc... Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

| Process: | CNC Machining, CNC Turning, CNC Milling, CNC Lathe, CNC boring, CNC grinding, CNC drilling etc... |

| Surface treatment: | Clear/color anodized; Hard anodized; Powder-coating; Sand-blasting; Painting; Nickel plating; Chrome plating; Zinc plating; Silver/golden plating; Black oxide coating, Polishing etc... |

| General Tolerance: (+/-mm) | +/-0.001mm or +/- 0.00004" |

| Certification: | ISO9001:2008, ROHS |

| Experience: | 15years of CNC machining products 3years of automation machine manufacturing |

| Lead time : | In general:7-15days Special custom service: making arrangement upon customers' request |

| Minimum Order: | Comply with customer's demand |

| Packaging : | Standard: pearl cotton and bubble bag, carton box and seal For large and big quantity: pallet or as per customers' requirement |

| Term of Payment: | T/T, Paypal, Trade assurance etc... |

| Delivery way: | Express(DHL,Fedex, UPS,TNT,EMS), By Sea, By air, or on your requirement |

| Maine equipment: | Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc. |

| Testing facility: | Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester |

| Item Tag: | mini cnc milling machine for sale |

| MEASURING CAPABILITY | |||

| Measurement | Range(mm) | Accuracy(um) | Brand |

| Length | 200×150 700×600×500 0-600 | 3+L/50 2.1+3.8L/1000 3+L/300 | Easson(Taiwan) Brown & Sharpe(Us) Trimos/Tesa(Swiss) |

| External Diameter | 0-100 | 1 | Mitoyuto(Japan) |

| Internal Diameter | 5-30 | 1 | Tesa (Swiss) |

| Surface Roundness | 80 | 0.01 | Mitoyuto(Japan) |

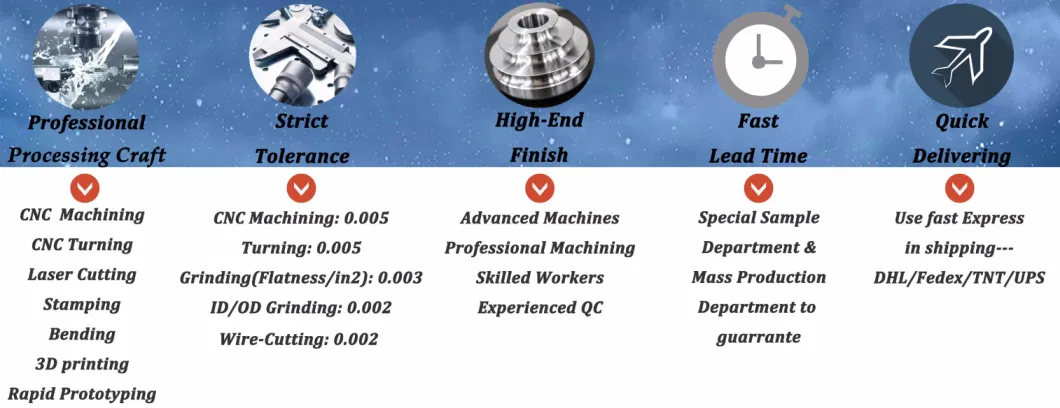

| General Tolerance(+/-mm) | |

| CNC Machining | 0.005 |

| Turning | 0.005 |

| Grinding(Flatness/in2) | 0.003 |

| ID/OD Grinding | 0.002 |

| Wire-Cutting | 0.002 |

| MAXHINING EQUIPMENT | |

| CNC Machining | Sheet Metal |

| High Speed Vertical Machining Horizontal Machining CNC Turning | CNC Blanking Hydraulic Shearing Hydraulic Press Welding |

| Grinding | W/C Machining |

| Jig Grinding Center-less Grinding Surface Grinding ID/OD Cylindrical Grinding Ceramic Grinding | Wire Cut Drilling |

| General Machining | Others |

| NC Turning Lathe Milling | Lapping Heat Treatment Surface Treatment |

[Our Quality Department]

We have special Quality Control Department to check the products before ship to clients, ensure the parts are good and precise, will meet your needs and requirements 100%.

If you need quality inspection report, we can offer it. Each order will have quality inspection report in record.

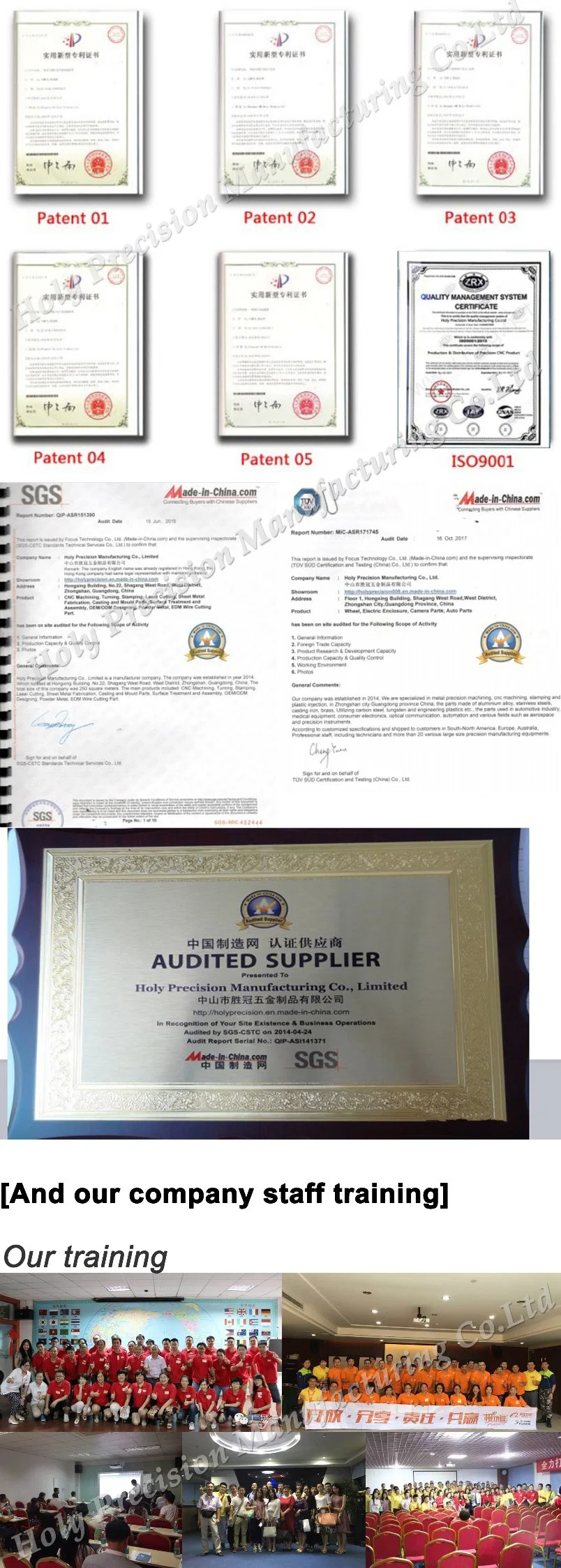

[Certifications]

[Customer's Visit]

welcome to contact us!

[WHY Choose Us?]

1. Long-term cooperation strategy for trustable business;

2. Professional manufacturer and supplier for 15 years;

3. 100% quality inspection before shipment: Defect rate less than 0.7%.

4. 1.5 million monthly export volume:we are still growing.

5.15 workshops & 4 partners to manufacture : No worry about your delivery time.

6.7/24hours online service: Responding to you anytime.

7. High grade material selection :Non-pollution for products.

8. High standard surface treatment: Safe & no deburr .

9. The lowest price with the same quality and service:Least money for best service.

[FAQ]

1. Q: Are you a factory or trading company?

A: We are factory, welcome to visit our company.

2. Q: What's the MOQ?

A: MOQ: sample order/batch production are both available. As per your needs.

3. Q: What is your warranty for the items?

A: Our inspector will check samples before mass production, after start production, we have inspectors check product every half an hour, before shipment, they will recheck parts to make sure it is good.

4. Q: What is the solutions if the parts don't meet specification?

A: If we found the parts don't meet specification before shipment, our inspector will reject it and we will arrange remake the parts. If you received the parts and found problems, please let us know, we will recheck the remain, and find good solution to solve.

---------------------------------------------------------------------------------------------------------------------------------------------

Thank you for your watching!!!

Welcome to Send your Inquiry Details in the Below, Click "Send" Now!!!